Qingdao Kunyuan Machinery Co.,Ltd.

Address: Mingguan Road No.729 Huangdao area Qingdao china

Phone:

13506429902

13963992990

Tel: 0532-86151277

Fax: 0532-89050585 86152277

Technical Advisory: 13506429902

E-mail: machinery66@aliyun.com

x2099@126.com

PRODUCT CLASS

Aluminum profile through shot blast..Marble Shot Blasting MachineH Type Section Steel Shot Blasting ..Gear Shot Blasting MachineIn Addition To Dust EquipmentsSteel Pipe Inner Wall Shot Blasting..Steel Pipe Outer Wall Shot Blasting..Big Steel Structure Shot Blasting M..Spring Shot Blasting MachineHoist Hook Shot Blasting MachineSteel Pretreatment Complete lineSteel Belt Shot Blasting MachineRebar Shot Blasting MachineSprayed The Pill MachineRoller Shot Blasting MachineRolling Drum Shot Blast Cleaning Ma..Vertical Steel Plate Shot Blasting ..Portable Shot Blasting MachineApron Tumblast Shot Blasting Machin..Anchor Chain Shot Blasting MachineWear-resistant Sparc-partsThe Blast WheelSpraying Sand RoomGas Cylinder Inner Wall Shot Sprayi..Gas Cylinder Outer Wall Shot Blasti..Tnclined Rolling Drum Shot Blasting..Bent Axle Shot Blasting MachineResin Sand EquipmentsCar Shot Blasting MachineNet Belt Shot Blasting MachineRubber Apron Tumblast Shot Blasting..Small Steel Pipe Inner Wall Shot Sp..Small Steel Pipe Outer Wall Shot Bl..The Tach Derrick Chain Cleaning Sho..Sand Processing EquipmentsHook-turntable Shot Blasting Machin..Trolley Shot Blasting MachineSucker Rod Shot Blasting MachineRotary table blasting machineSteel plate profile surface cleanin..

CONTACT US

Company Address: No.427 lingqueshan road huangdao area Qingdao

Postal Code: 266400

Phone: 13506429902

13963992990

Tel: 0532-86151277

Fax: 0532-86152277

Technical Advisory: 13506429902

E-mail: machinery66@aliyun.com

x2099@126.com

News

Introduction to clay sand cooling system

In the process of clay sand casting, in order to improve the production efficiency and recycle the old sand, it is necessary to treat the old sand by crushing, magnetic separation, screening, cooling, transportation and other processes; The system uses simple, reliable and mature sand processing equipment to form an assembly line, and the recovery rate of used sand is ≥ 95%; The design scheme not only meets the user's requirements for the quantity and quality of castings, but also strives to be simple, practical, easy to operate and less vulnerable parts. Due to the strong comprehensive function of the main equipment, the number of auxiliary machines can be reduced, the intermediate links can be reduced, and the reliability can be improved. The line has the characteristics of high efficiency and low consumption, compact structure, flexible layout, reliable use, and has achieved electromechanical integration.

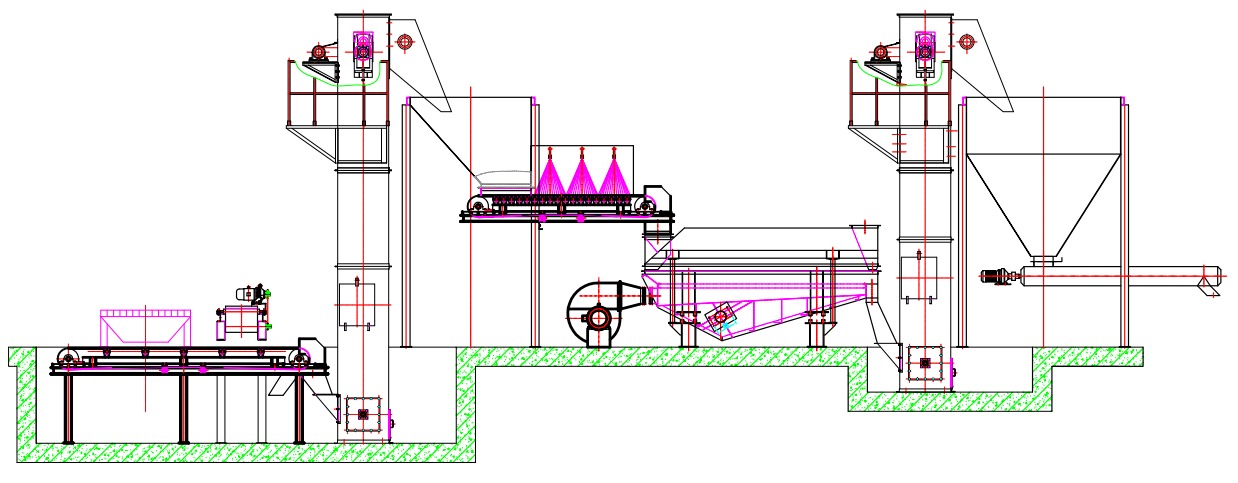

Technological process:

Manual sand cleaning - hopper with grating - heat resistant belt conveyor - magnetic separator - elevator - sand silo - heat resistant belt conveyor - automatic water spraying system - boiling cooling bed - sand temperature measuring device - elevator - sand silo - screw feeder - Modeling Department;The whole system uses pulse dust collector to collect dust.

Structural characteristics and functions of main equipment

The cover is formed by bending and welding of steel plate, with neat appearance, good sealing performance, simple structure and rigidity The degree is also good. The transmission is composed of reducer, sprocket, chain and tensioning device. The door cover on the hoist hood can be used to repair and replace the hopper. The door cover on the lower hood can be opened to repair the lower drive and eliminate the accumulation of bullets at the bottom.

Belt and hopper are the transport parts of materials. The hopper is connected to the belt by nuts, and the annular belt drives the hopper to lift materials.

Lifting capacity 5 t/h

Power 1.5 kw

The machine uses roller and shaft mounted reducer as the driving device, which takes up little space, and at the same time Magnetization separation task, easy installation and maintenance; The upper idler is clamped and fixed, which is easy to install and has strong ability to adjust the deviation of the conveyor belt. The material conveying system can be equipped with dischargers, sweepers, dust covers, etc. according to the actual situation.

Belt width 500 mm

Conveying capacity 5 t/h

Power 1.5 kw

Purpose:It is used for cooling the hot old sand recycled in the casting production line of the casting workshop.

Principle:The temperature of the used sand after pouring is generally 70~120 ℃, and the moisture content is less than 2%. When the type of shakeout machine is unreasonable, such as some shakeout drum, the casting and used sand are screened and separated until they reach the end of the drum. The heat exchange time is long. The hot casting will heat the used sand to high temperature and dry, the temperature can reach 120~180 ℃ or higher, and the moisture content is less than 1%. At present, many casting production lines adopt 2~3 shifts of efficient operation mode. The old sand has many turnover times, short cycle, fast heating, and the hot old sand is also too high and too low. This kind of dry and hot used sand has low thermal conductivity, and the cooling effect of air cooling alone is very poor. For example, the wind speed of hot and used sand is more than 20 meters/second, and the wind speed of cooling elevator is 10 meters/second without humidification. The used sand can only be reduced by 10 to 20 ℃, far from meeting the process requirements.

According to the data obtained by the long-term theory and production practice of the foundry workers, the intense blast convection can reduce the latent heat of vaporization carried away by 1% moisture evaporation in the hot and humid old sand by 25 ℃. Therefore, it is an effective way to solve the problem of large production rate of used sand cooling to develop an automatic control instrument for temperature measurement and water humidification of used sand and a cooling equipment for convection, high efficiency vaporization and evaporation of used sand.

Cooling sand volume 5t/h

Sand inlet temperature 90~140℃ (up to 160 ℃)

Sand production temperature 15~45℃

Water content of treated sand 1.5~2.5%

Cooling efficiency 85~88%

Water consumption 150-200kg/h (5t/h)

Fan power 7.5kw

Vibration motor power 2*1.5kw

4.Automatic water filling system

Automatic adding system: the thermocouple detects the temperature of the cooled sand and automatically starts the spray system; Reduce the hot sand to a proper temperature.

The automatic water spraying system is composed of nozzles, solenoid valves, water pumps, buckets, pipes, etc; The sand temperature measuring device automatically measures the sand temperature and feeds it back to PLC; After being processed by PLC, the water spray valve can be automatically controlled to start and stop, so as to add appropriate water volume.

Pump flow 6.3m3/h

Power 1.1kw

5.Sand temperature measuring device

The sand temperature measuring device is composed of thermocouple, temperature display instrument, temperature control module, etc; Thermocouples automatically measure the temperature of sand and feed it back to PLC to automatically control the automatic water spraying system.

6.magnetic separator

Main purpose:It uses magnetic force to separate ferromagnetic materials from non-magnetic materials to protect process equipment such as crushing, screening, lifting, feeding, mixing machine, molding machine, etc; Equipment for normal transportation and scrap iron recovery.

Belt width 500 mm

Conveying capacity 5 t/h

Power 1.5 kw

The machine uses permanent magnet roller and shaft mounted reducer as the driving device, which takes up little space, and at the same time Magnetization separation task, easy installation and maintenance; The upper idler is clamped and fixed, which is easy to install and has strong ability to adjust the deviation of the conveyor belt. The material conveying system can be equipped with dischargers, sweepers, dust covers, etc. according to the actual situation.

Belt width 500 mm

Conveying capacity 5 t/h

Power 1.5 kw

The overall design idea of dust removal is that the dust removal effect must be better to ensure the effective discharge of dust. MC80 pulse bag filter; The total air volume of the whole line is about 15000m8. З/ h. Each dust removal point is designed with an air volume gate to regulate the air volume, and the main air duct is equipped with a butterfly valve to regulate the air volume.

Air volume 15000 m3/h

Power 15kw

Purpose:This series of screw feeder is applicable to the feeding of non-wet granular materials, and can be used as a uniform feeding device or a quantizer. The material enters the screw feeder through the feed bin above the screw feeder through the adjustment plate. When the motor rotates, the rotary motion of the motor drives the spiral body of the screw feeder to rotate through the deceleration motion of the cycloidal pinwheel reducer, thus pushing the material forward. The material is sent out through the outlet at the lower part of the screw feeder shell to complete the feeding action.

Conveying capacity 20 t/h

Power 1.5 kw

10.Electrical system

Siemens PLC and touch screen are adopted. Automatic control is adopted for the whole line, but the front and back of the equipment are interlocked to protect the equipment; Each equipment can also be operated individually to prevent production from being affected during equipment maintenance.